Remain competitive thanks to vertical automated warehouses: integrated management of processes as a strategic benefit

The strong competitive push from the market requires a much faster response from companies in their management of internal processes: having solutions that speed up and automate flows has become a must to gain a preferential place against competitors.

The strong competitive push from the market requires a much faster response from companies in their management of internal processes: having solutions that speed up and automate flows has become a must to gain a preferential place against competitors.

One of these processes is undoubtedly warehouse automation.

Managing a warehouse with organizational efficiency does not just mean containing costs; it means working precisely and reliably.

Matteo Bevini is the Non Food Sales Director and Manager of the STS | Storage & Transportation Solutions division. Fully dedicated to automatic storage and AGV vehicles, STS is the result of wanting to offer customers a single reference for all those needs linked to handling goods and materials and to designing integrated solutions, whilst guaranteeing the quality standards and 24/7 assistance that makes EMS Group products stand out.

What do we mean by automated warehouses and what are the main benefits compared to traditional ones?

The automated warehouse is a system that optimizes all intralogistics operations – from receiving goods to storage, on to preparing orders and shipments – thanks to technologies implemented to handle goods automatically and software to coordinate operating cycles, often integrated with company management systems.

Using automated warehouses increases the speed, efficiency and safety of all activities.

The productivity level increases as mistakes made when managing stock decrease and the response to market requests is punctual and efficient; costs drop as the automated handling of goods minimizes the possibility of damage to storage structures and finished products, besides decreasing human errors. Therefore, the initial investment can be recovered fast.

Compared to traditional warehouses, you can recover up to 80% of the space. An automated warehouse can exploit warehouse height in full, the space between lanes is reduced and the software optimizes stock management to use storage facilities in the best way possible.

The increase in workplace safety is definitely one of the main benefits of implementing automated warehouses: the automation of handling processes drastically reduces risks for operators, in particular in companies foreseeing frequent pick-up and placement operations.

The automated warehouse is a complex system that integrates human resources and technology to improve performance; it has become a strategic element for increasing the competitiveness of any company and sector.

How many types of automated warehouses are there?

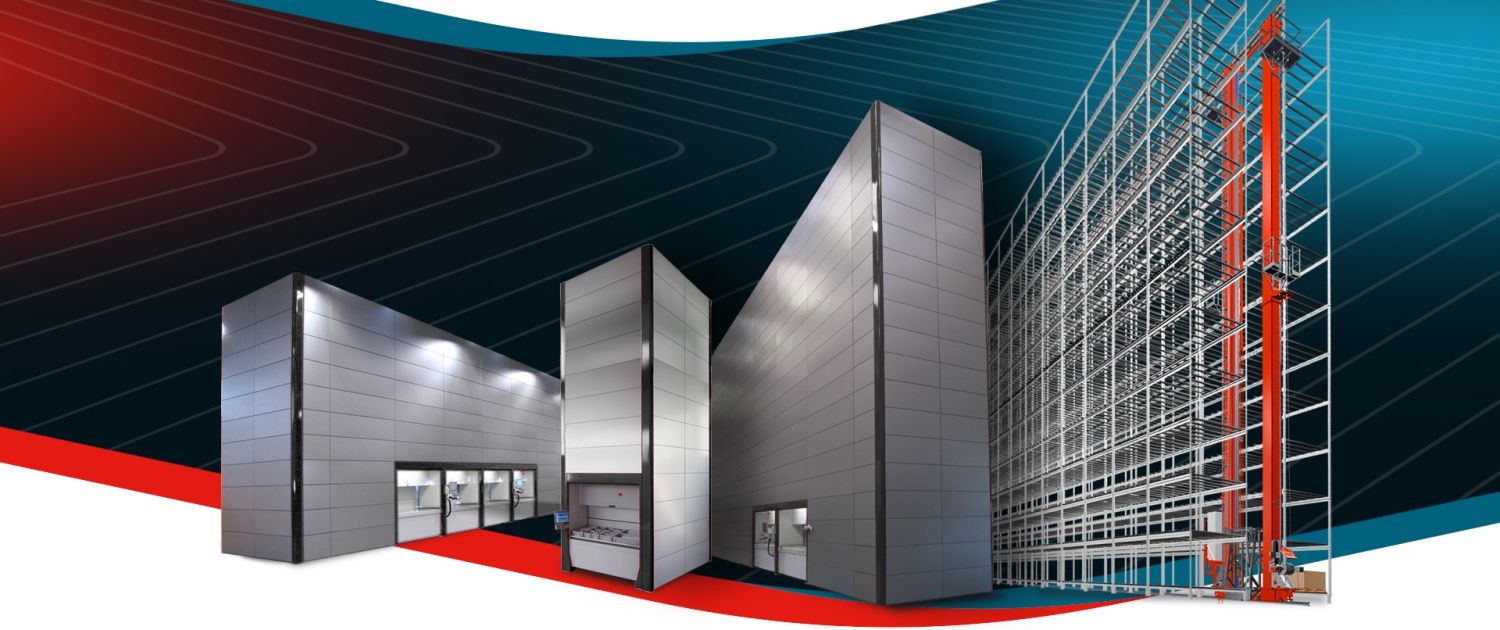

EMS Group creates two types of automated warehouses: automated warehouses for trays and stacker cranes. This wide range enables us to offer each customer the solution best-suited to its needs.

The automated warehouses for trays are ideal for storing products that come in different sizes, optimizing space and speeding up pick-ups.

The basic concept is that of “dynamic shelving”: the tray itself is the shelf, thus reducing the empty spaces normally found in traditional shelving to a minimum.

Automation applies the “goods to man”concept: products are delivered to a pick-up bay, the operator does not have to move for either the pick-up or the placement.

One of the main strongpoints is the increasable storage capacity based on need.

EMS Group offers a wide range of vertical warehouses for trays:

- UNO, automated warehouse with single module, 2 axes, one bay.

- SPACE, automated warehouse with 2 to 10 modules, 3 axes, one or more bays.

- UNICO, automated warehouse multi-module with no limits in length, 3 axes, one or more bays.

All three solutions can be installed both inside or outside and reach maximum 14 meters in height.

Served by AGV, FLS (Fast Loop System) or traditional conveyors, stacker cranes are designed for the automated and intensive storage of loading units (for example pallets). Thanks to different pick-up systems and three machine types, they are a safe, efficient solution for all sectors. Furthermore, they can also work at temperatures below 25 °C. The structure types are:

- single-column, ideal for storage up to 25 meters in height;

- double-column, suited for heights over 25 meters.

- with shuttle to level, suited to any height, typically for high flow warehouses.

Talking about automated management, how do companies deal with this kind of change?

During the Covid-19 emergency, companies that had already automated storage processes were less penalized by the pandemic and lockdown. This made many others understand the benefits provided by product process automation, starting from managing logistics and storage.

Automation also improves work quality, as managing these systems requires increasingly more specialized operators, much sought-after resources and of fundamental importance for company progress and success.

What are the next challenges for the future of logistics?

The business is going through a period of great change. The strong push towards the digitization of processes, promoted by incentives such as INDUSTRY 4.0, indicates that the automation of logistic processes is the right route.

Our vision of the warehouse of the future foresees using technology to simplify work and make performance even more efficient, moving towards operation flexibility. For example, this latter concept is expressed in the use of automated sorting systems and includes using robots to manage picking and for handling. Technology has infinite potential nowadays. It is up to us to understand how to grasp and adapt it to our business and EMS can count on know-how acquired in several sectors.